Ceramic drilling is a specialized process that has gained popularity in various industries due to its unique properties and performance benefits. With its exceptional resistance to heat, corrosion, and wear, ceramic materials are sought after for their durability and longevity. However, drilling through ceramics can be a challenging task that requires precision and the right techniques. If you are looking for the right Ceramic drilling services then contact UKAM Industrial Superhard Tools.

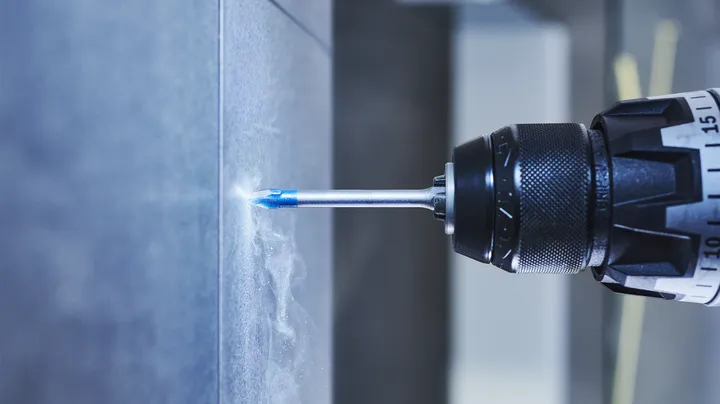

When it comes to ceramic drilling, it is essential to use the appropriate tools and techniques to ensure successful and efficient results. One of the most critical factors is the selection of a high-quality drill bit specifically designed for drilling through ceramics.

Image Source: Google

These drill bits are typically made of tungsten carbide or diamond, known for their hardness and ability to withstand the hard nature of ceramics. Another vital aspect of ceramic drilling is the speed and pressure applied during the process. Unlike drilling through metals or wood, ceramic drilling requires a slow and steady approach to prevent cracking or chipping.

Ceramic drilling is commonly used in various applications, including aerospace, automotive, electronics, and medical industries. In aerospace, ceramics are used for turbine components, ceramic matrix composites, and thermal protection systems.

The automotive industry utilizes ceramic drilling for brake components, engine parts, and cutting tools. In electronics, ceramic materials are commonly used for insulating substrates, circuit boards, and semiconductor devices. In conclusion, ceramic drilling is a specialized process that requires precision and the right tools to achieve successful outcomes.