Selective Laser Sintering (SLS) printers represent a groundbreaking advancement in the realm of additive manufacturing, offering unparalleled precision, versatility, and design freedom. By harnessing the power of laser technology and innovative materials, SLS printers enable the creation of intricate and durable components with exceptional accuracy and detail. This website offers an extensive collection of SLS printers, from basic models to the more advanced and sophisticated varieties.

Principle of Operation

At the heart of Selective Laser Sintering printers is the principle of sintering, a process wherein powdered materials, typically polymers or metals, are fused together using a high-powered laser beam. Layer by layer, the laser selectively sinters the powdered material based on the digital design data, gradually building the desired component with exceptional precision.

Versatility in Material Selection

One of the defining features of SLS printing is its versatility in material selection. From durable thermoplastics and engineering-grade polymers to specialized metal powders, SLS printers support a wide range of materials, each offering unique properties and performance characteristics tailored to specific applications and requirements.

Complex Geometries and Design Freedom

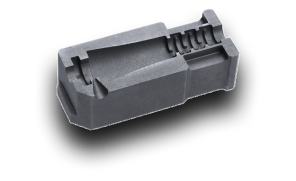

SLS printing empowers designers and engineers with unparalleled design freedom, enabling the creation of complex geometries, intricate structures, and integrated functionalities that are challenging or impossible to achieve with traditional manufacturing methods. This design flexibility fosters innovation, encourages experimentation, and facilitates the development of optimized and customized solutions.

Cost-Efficiency and Scalability

Despite its sophisticated capabilities, SLS printing offers cost-efficient and scalable manufacturing solutions. By minimizing material wastage, streamlining production workflows, and eliminating the need for tooling or molds, SLS printers enable efficient batch production, rapid prototyping, and on-demand manufacturing, making it a cost-effective and adaptable solution for diverse applications and industries.

In conclusion, Selective Laser Sintering (SLS) printers stand as a testament to the transformative power of additive manufacturing. With their unparalleled precision, material versatility, and design freedom, SLS printers have redefined the boundaries of what's possible in product development and manufacturing.